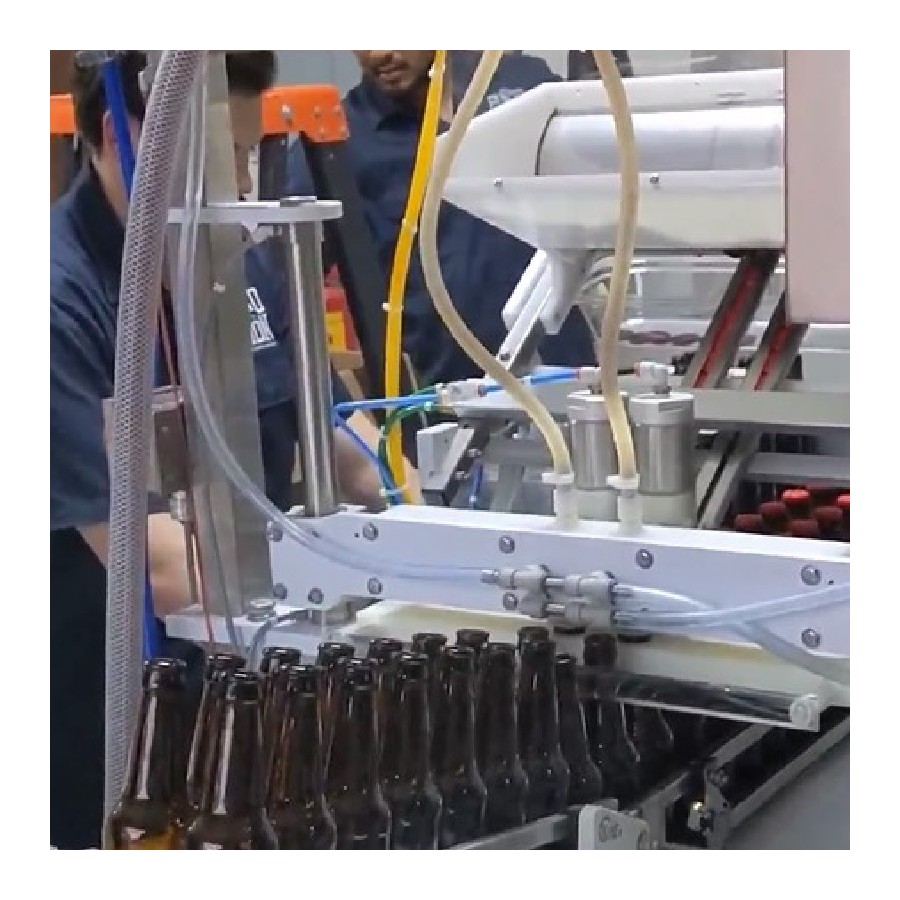

Ramp up your bottling quickly and efficiently.

Our filling technologies help premium brands ramp up bottling production affordably and quickly. A Meheen fully-automated, pneumatic powered filler can produce up to 2,400 bottles per hour and help you increase distribution, revenues and profit margins from the first bottle and beyond.

Characteristics

- Automatic counterpressure filling with 2, 4 or 6 fills heads

- Automatic crowning

- Semi-automatic rinsing

- Dimensions: 5.5′ L x 3.5″ W (1.7 m L x 1.1 m W)

- Power: Single-phase 17A @ 115VAC, 50/60 Hz or 9A @ 230VAC, 50/60 Hz

- Air: Clean, dry compressed air required at 15 cfm @ 90 psi (25 m3/h @ 6.2 bar); refrigerated air dryer and coalescing air filter rated to 0.10-0.01 micron required

- CO2: Up to 12 cfm @ 40 psi

- Training: Onsite for 2-3 days