Capping Machines by Inline Fillers

Inline Filling Systems has engineered complete liquid filling lines for over 20 years. The typical filling line is composed of filling, capping and labeling machinery ENTIRELY built and supported by Inline Filling Systems in the USA. Other complex systems that include sophisticated third party equipment from our USA business partners are also entirely engineered, integrated, tested and installed by us in our complete lines.

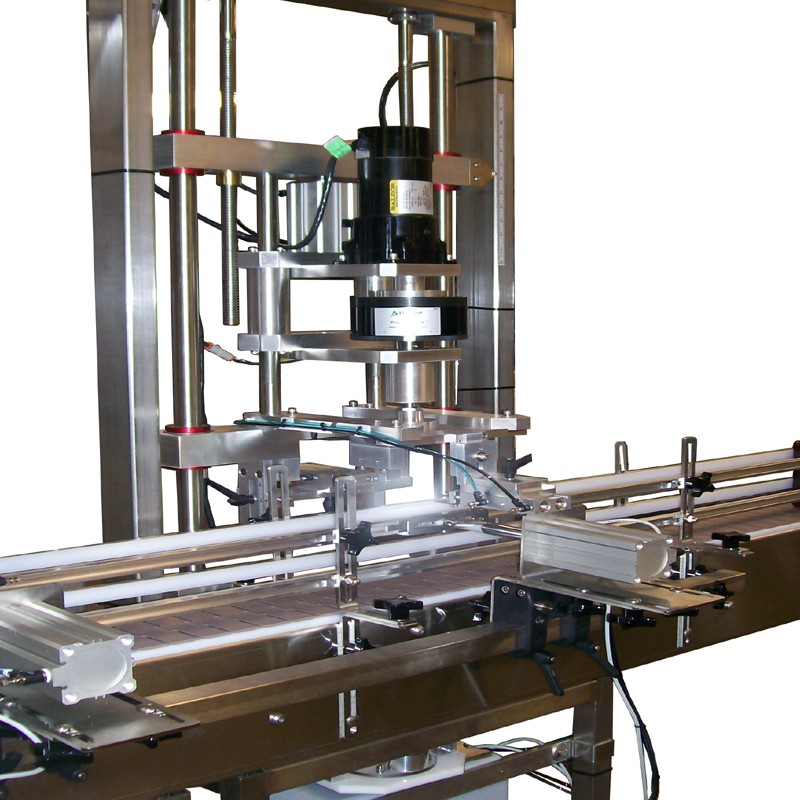

Capping Machines

Used for water thin liquids with no particulates and whose bulk density and flow characteristics do not change with atmospheric or temperature changes. Usually specified in chemical environments where recirculation is not practical. The time gravity filler is an effective low-cost technology with limited flexibility.

Capping Machine Selection Guide

Capping machines are used for the application of plastic and metal threaded caps as well as plastic snap caps, some fitments and some types of corks and plugs. Capping is usually the most difficult aspect of a liquid packaging line for several reasons. Sometimes the range of geometries and sizes of caps and bottles is so wide that the capping machine components become expensive or the platform of that particular type of capping machine is not suitable for all sizes and geometries in the range.

Sometimes the bottle and cap combination are not ideal with the threads of the bottle being in conflict with the threads of the cap and great force is needed to apply the cap. Sometimes caps can only be placed vertically on the container which increases the capital cost of the machinery. Inline Filling Systems understands these issues very well and has a capping machine to address every one of these capping challenges. We specialize in capping machines and cap feeding systems for both startup companies as well as higher speed production environments.

Machine Catalog

- Automatic Capping Machine

- Semiautomatic Capping Machine

- Automatic Cap Tighteners

- Feeders & Sorters