Nitrogen Dosers

How does nitrogen dosing work?

Based on the physical characteristic that one part of liquid nitrogen warms and expands into 700 parts of gaseous nitrogen at ambient temperature, Chart’s automated dosers dispense a precisely measured dose of liquid nitrogen (LN2) into each container prior to sealing.

Reducing waste and cost one drop at a time

The trapped liquid nitrogen vaporizes, creating pressure, and adding rigidity to the container – allowing for a thinner container wall. For preservation and modified atmosphere packaging (MAP) applications, the rapidly expanding gas is allowed to escape before the product is sealed, flushing out oxygen, and extending product shelf life.

Using Chart dosing technology in their production lines enables a vegetable oil producer to use lightweight PET bottles saving >700,000 kg of plastic. That’s the equivalent of 24 adult humpback whales.

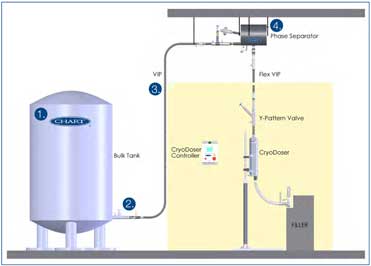

Complete Turnkey Solution

From initial design to a complete after-sales package, we work closely with our customers to ensure that the complete system is engineered and built in accordance with their requirements and always operating at peak efficiency. Chart delivers the highest levels of performance at the lowest operating cost with single source accountability for your project.

Packing

A precise dose of liquid nitrogen is delivered immediately before capping or seaming. The trapped liquid nitrogen quickly vaporizes, pressurizing the container. In hot fill applications the nitrogen pressure counteracts the vacuum created when a hot product cools.

Key Benefits: lighter weight packaging, increased packaging rigidity, glass to plastic transition, eliminates package paneling, ease of labeling, oxygen reduction

Typical Applications: bottled water, energy shots, flax seed oil, juices (hot and ambient fill), teas, vinegar

In Operation: documented 9 gram reduction in PET bottle weight with Chart’s MicroDose™ technology. Assuming the PET resin cost of $0.80/lb and a single production line running at 700 bottles/minute, this equates to an annual cost saving >$2.6 million

Preservation

An exact dose of liquid nitrogen is introduced seconds before the seamer or capper. The volumetric expansion of the vaporized nitrogen pushes oxygen out of the container.

Key Benefits: oxygen reduction, extended shelf life, efficient nitrogen consumption, stabilization of organic products

Typical Applications: automobile oil, beer, condiments, wine

In Operation: documented studies show a 26% increase in shelf life and 90 to 95% reduction in headspace oxygen compared to traditional gaseous nitrogen purging

Freezing

A dose of liquid nitrogen is introduced to “lock in” and surface freeze the product before it’s transferred to a traditional tunnel or spiral freezer.

Key Benefits: maintains product integrity, aids in packaging and labeling, enables new products to be brought to market, enhances flavor and texture

Typical Applications: dipped ice cream cones and iCream Café

In Operation: liquid nitrogen flash freezing of ice cream cones provides stability and support through the packaging process resulting in improved overall aesthetics

Modified Atmosphere Packaging (MAP)

A large dose of liquid nitrogen is introduced into the package seconds before the seamer or capper.

Key Benefits: extended shelf life, oxygen reduction, reduced nitrogen consumption, stabilization of organic products

Typical Applications: baby formulas, coffee, nuts, trail mix, botanicals

In Operation: 46% reduction in nitrogen consumption using a Chart doser in lieu of traditional nitrogen gas purging

Superior Dosing Technology

Places or sprays liquid nitrogen on the surface of the product rather than penetrating the product surface, essentially eliminating any product splash and delivering consistent container pressure. Can be tailored to a specific product, package or application.

Developed in response to market demands to precisely dose liquid nitrogen into ultra light weight packaging to comply with tight container pressure specifications. Incorporates multiple sensors to detect variables such as filling line speed and bottle presence, that the system uses for fine tune elctronic adjustments.

Permits control access to via the customer’s intranet enabling engineers to view the process, create and load recipes and trouble-shoot from a desktop PC, laptop or mobile device. Actions that previously required multiple staff for a large-sized machine or long-distance application are easily accomplished with significantly fewer operators.

Choosing Your Doser

Chart liquid nitrogen dosing equipment is easy to operate and can be integrated into new or existing packaging lines.