POST-FILL

The Ska Fabricating™ Can Rinse and Drying System

Our custom can rinsing and drying system is a perfect addition to your canning line. The system uses Republic® air knives combined with our custom designed can rinser and enclosures.

Our can rinser is specifically designed for cleaning cans after the canning process. It removes excess liquid and cleans the cans before packaging. The enclosure is made of stainless steel and incorporates 6 water nozzles. Water is collected in the bottom catch basin and drains through a 1″ fitting.

The air knife enclosure is also made of stainless steel and both enclosures have top handles for easy removal. The lids are secured with screw on fasteners making the cleaning process quick and easy.

FILL LEVEL DETECTION

The Filtec 3 – Full container inspection detects over and under filled containers and capping defects. It inspects for over filling and under filling cans or bottles, and if the can end or bottle lid are fitted correctly. The Filtec 3 inspection system detects these issues as they arise on the filling line, as well as identifying bulged cans, high or low foam levels, glass bottle breakages, containers falling over on the line, and where applicable, missing foil seals.

The system is capable of handling filling line speeds – it runs at up to 2,400 cans a minute or 1,400 bottles a minute – and collects data as it goes, keeping count of the total number of containers analyzed and the total number of rejected parts. It also offers real-time continuous statistical analysis of the data, and uses sampling to monitor the performance of filler valves and the capping and closing heads, enabling the system to identify if a fault within an individual station is causing rejects.

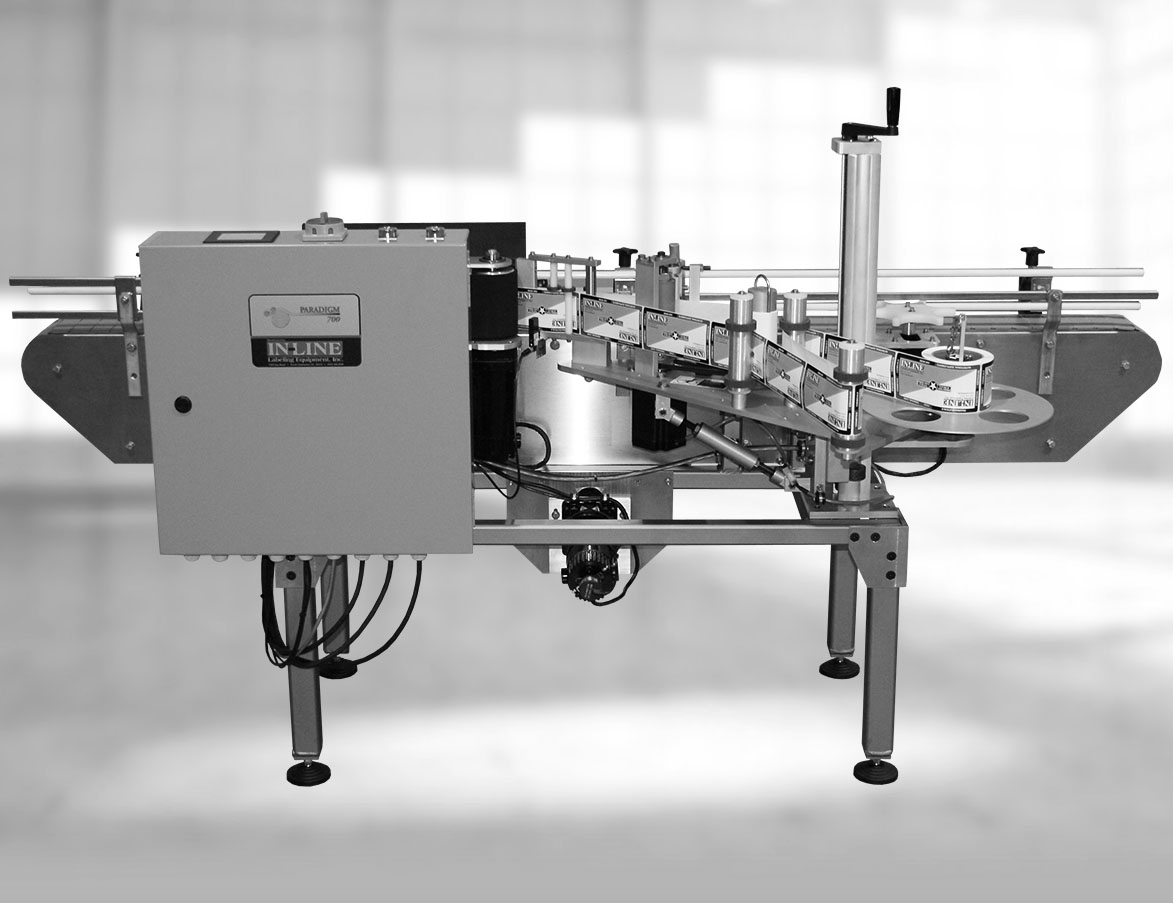

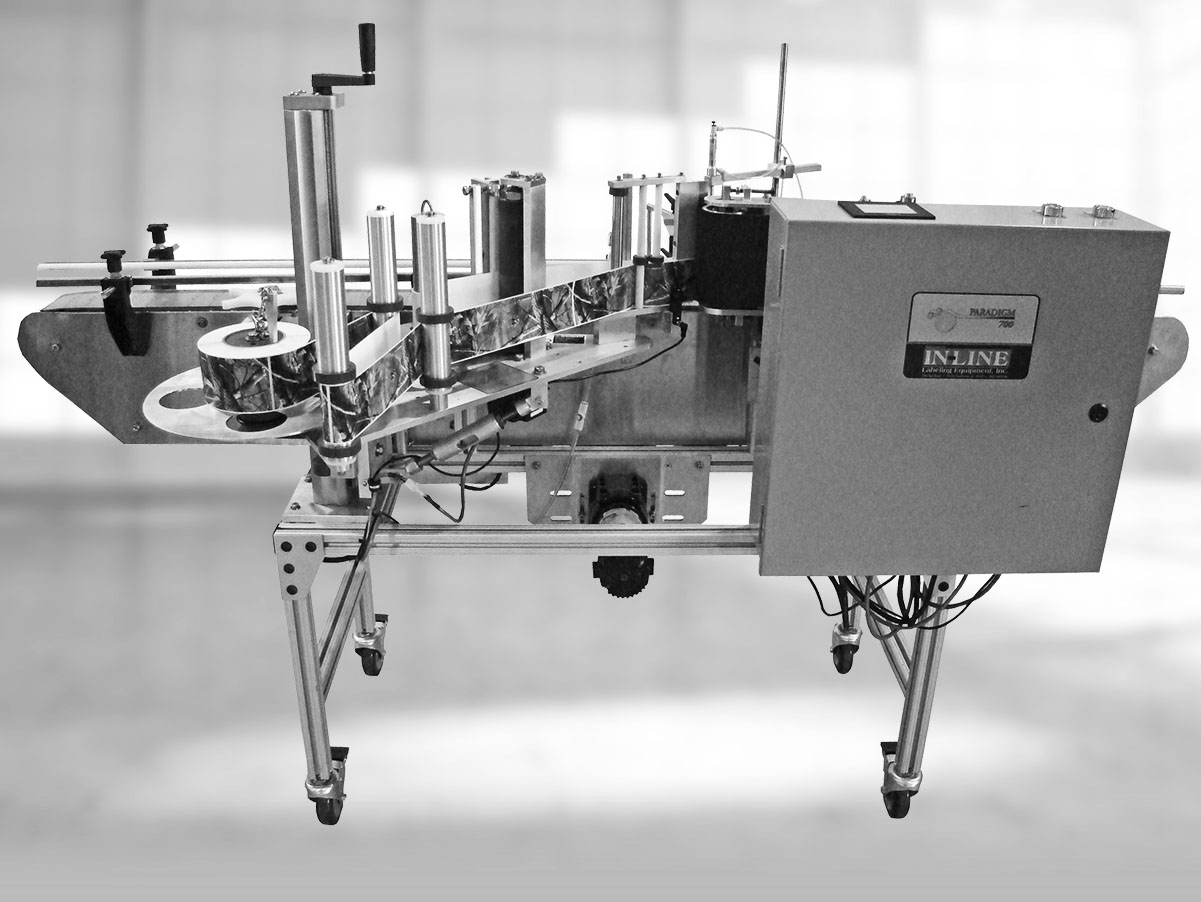

LABELERS

The Paradigm 700VS is a completely new shift from current designs. It can be ordered as one configuration now and easily changed in the future by replacing or adding bolt-on parts. The conveyor height, width, and length can be reconfigured, along with the direction of the machine (left hand or right hand) and one of three labeling styles – wrap, spin-in place, or trunnion style. The machine features all stainless steel and aluminum construction, off-the-shelf components rather than proprietary boards and motors, a stepper-driven applicator and a standard Touchscreen interface on all models.

HANDLE APPLICATOR

The American Canning PakTech Handle Applicator has a compact footprint and simple, yet robust design. It delivers full-sized machine performance to small craft beverage producers.

Line Compatibility: Ideal for in-line and conveyor belt-fed canning lines but designed to work with virtually all makes and models, including small to mid-sized rotary machines and conveyor-type «non-counter pressure» equipment. Essentially, if you can get your cans onto the built-in conveyor, the applicator will take care of the rest. They’ll build the conveyor deck height to order.

CAN CARTONERS

The Switchback Group offers some of the most innovative and flexible End Load Cartoners and Case Packing equipment on the market. The BrewPack 200 features heavy duty construction with stainless steel frame. Ethernet based Allen Bradley PLC controls, variable frequency drives and servo axes which allow for product control throughout the machine cycle. Common settings can be stored and are available on the touchscreen controls.

The BrewPack 200 can run multiple can heights (12, 16 & 19 oz.) and multiple pack patterns (2×2, 2×3, 2×4, 2×6, 3×3, 3×4, 3×5, 3×6 and 4×6) which offers the ultimate flexibility.