PRE-FILL RINSERS

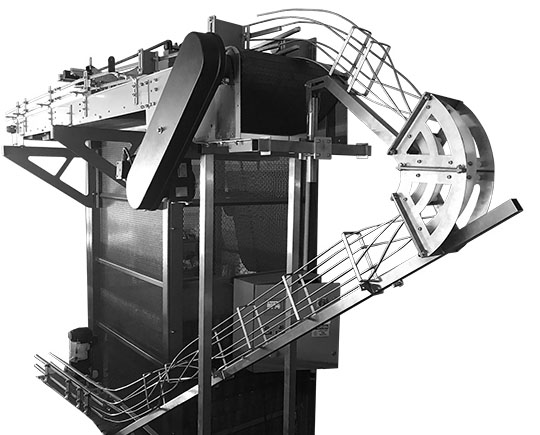

TWIST RINSE CAGE

The Zero Footprint Rinser makes it possible to run a smaller footprint canning line than ever before. This pre-fill can rinser is an easy add-on to your depal or conveyance system, saves considerable space and was designed with the specific goal of saving space in smaller production spaces without sacrificing the power of a full canning line. The ZFR is configured with one 90˚ section allowing cans to reverse direction prior to rinsing. Can be mounted straight or at a 90˚ angle. The rinser is made of stainless steel and is recommended for line speeds up to 120 cans per minute. It can be mounted to all standard canning lines and is available in multiple can sizes.

DUAL TWIST RINSE CAGE

Our Dual Twist Rinse Cage makes changing can sizes a breeze. No tools are needed. You simply slide the rinse cages from one side to the other and you’re ready to go. The dual twist rinse incorporates integrated can height controls. A sensor detects the active side of the rinse cage and controls which photo-eye to use so no adjustment is required. An automatic valve switches the water supply from one side to the other saving water and eliminating the need to unhook your water source. Saves time and money.

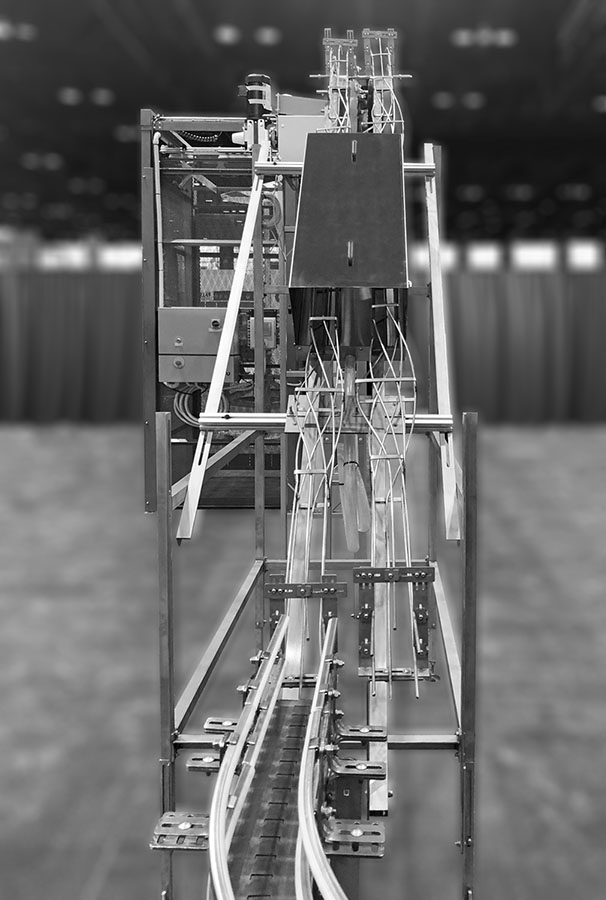

ZERO FOOTPRINT RINSER

The Zero Footprint Rinser makes it possible to run a smaller footprint canning line than ever before. This pre-fill can rinser is an easy add-on to your depal or conveyance system, saves considerable space and was designed with the specific goal of saving space in smaller production spaces without sacrificing the power of a full canning line. The ZFR is configured with one 90˚ section allowing cans to reverse direction prior to rinsing. Can be mounted straight or at a 90˚ angle. The rinser is made of stainless steel and is recommended for line speeds up to 120 cans per minute. It can be mounted to all standard canning lines and is available in multiple can sizes.

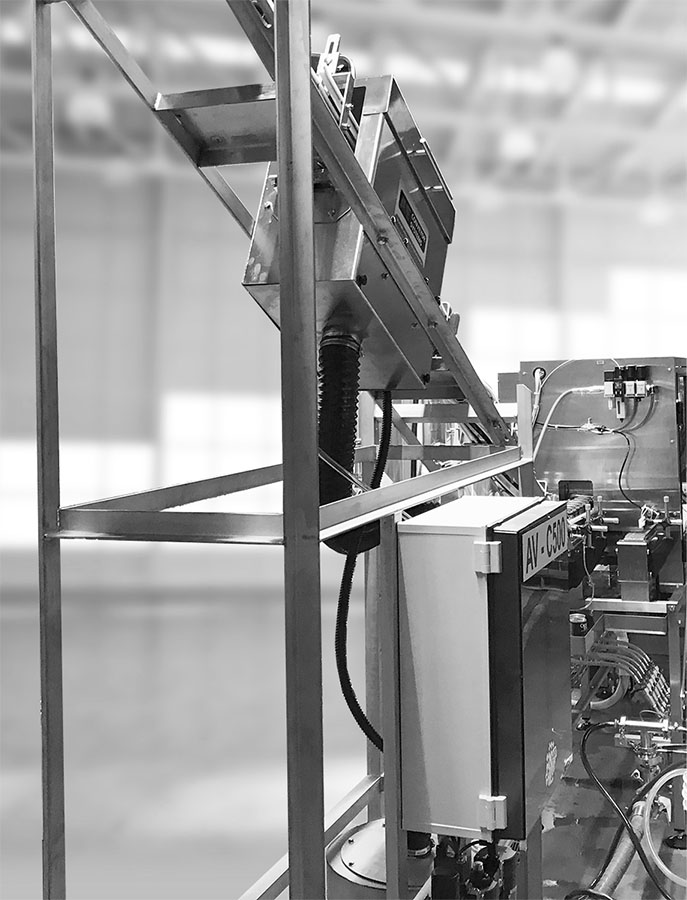

IONIZED AIR RINSER

A&E Conveyor Systems pioneered the waterless rinsing technology. They were the first company to introduce a commercially acceptable system for replacing conventional water rinsing systems. Historically the canning industry has used a simple water rinse ever since the introduction of non-returnable containers. The waterless rinsing systems are designed for higher speed canning lines. We recommend using Ionized Air rinsing for lines running at 110 cans per minute or above. The A & E Pur-Rinse system is based on their patented Air-Vac technology. The Air-Vac principle uses high pressure ionized air as the cleaning agent, combined with a continuous vacuuming process at the opening of the container to help remove and collect debris from containers. The A&E system uses an advanced ionization process that has built in diagnostic features along with an internal alarm function to provide assurances that the ionization system is operating correctly. The Air-Vac and the Advanced Ionization Controls are the two key elements that differentiate any other air rinse system from an A&E Pur-Rinse system.

CARLETON HELICAL

The CE Ionized Air Rinser is designed to integrate into packaging lines for glass, plastic, metal or fiber containers. The System utilizes the BMH Invertor/Revertor System to rotate containers over an Ionized Air/Vacuum Assembly. By supplying clean, dry shop air to the ionized air nozzles, it produces a turbulent airflow that pulls the debris towards the vacuum and ionizing nozzles. Removing the filter bag and replacing it with a new bag will eliminate debris that may collect in the filter. Some of the key components include Stainless Steel tubular frame construction with locating pins for quick and easy changeover of the BMH Invertor/Revertor Assemblies. AC Sew Eurodrive motors that can be matched for specific applications are utilized. The electrical boxes are NEMA 12 rated for our standard, but other NEMA ratings can but used according to specifications. The Ionized Air Rinser can be wired to 230 or 460 VAC or whatever voltage is necessary. The control wiring is simply 110 VAC.