Seltzer Pilot/Commercial System

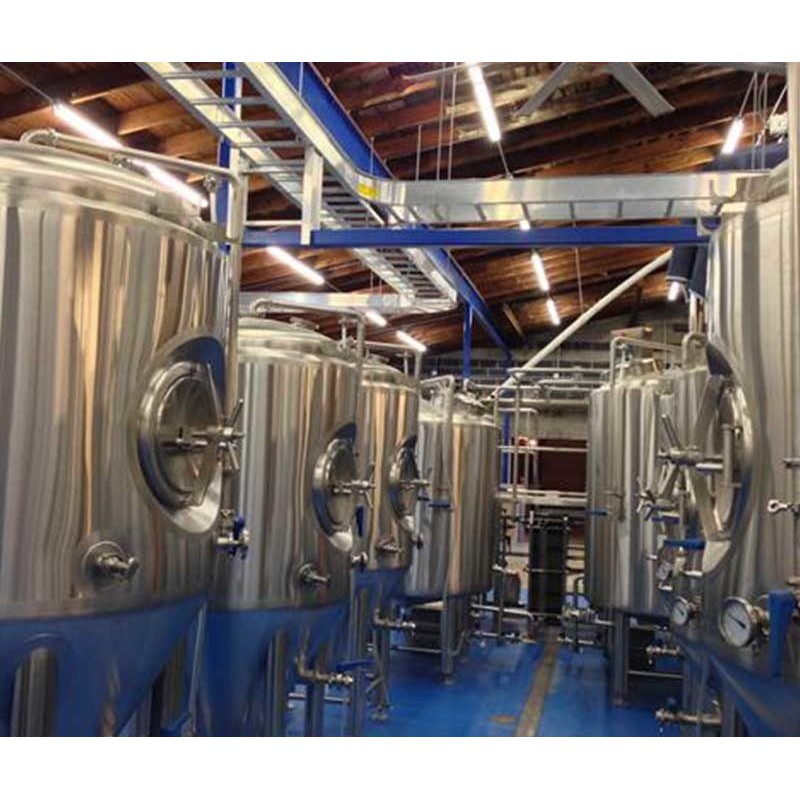

Craft Brewing Equipment

Craft Brewing Equipment is designed to support every stage of the brewing process, delivering the precision, consistency, and reliability required by modern craft breweries. From brewhouses and fermentation tanks to temperature control and sanitary systems, this equipment enables brewers to maintain quality, optimize efficiency, and scale production while preserving the character and integrity of their beer.

Image Gallery

Description

- Boil– Whirlpool Combi Vessel for the mixing of your water with malted base

- Dual Stage Heat Exchanger: For knockout at precision temps for fermentation

- Infusing Vessel: For your fruit, concentrate, spice, or hop additions that are not in the boil

- Integrated CIP Assembly

- Optional Steam Condenser

- SPX class c pump with ABB motor assembly integrated into customizable hard-piped design

- IFM temperature probes and connectivity

- Siemens 4″ HMI to control pump speed, vessel temperatures, and lighting. All electrical components UL certified

Kombucha Tanks

- Grated false bottom to support your scoby at manway-level

- 17″ x 13″ manway designed for easy scoby removal

- Co2 / o2 stone located under false bottom for oxygen dosing or carbonation

- Tangential inlet for mixing fruit and flavorings

- Designed to work with the deutsche tilting infuser

- Single-wall or glycol jacketed models available

- Rated to 29 psi

- Full CIP capacity

- Custom options available

Cold Brew Coffee

- Insulated, jacketed tank for hot or cold steeping applications

- Standard sizes= 150, 225, 300, 450, 600 gallon

- Automated control system with panel

- Complete sanitary hard-piped process and cleaning piping with centrifugal pump

- Variable-frequency motor driven agitator with material out plow

- Dual stainless-steel filter columns for selectable micron bag filters

- Power available in 240v (3ph) or 480v (3ph) for all systems and 220v (1ph) for 300 gallon systems and smaller

- Custom adaptions to meet your process specific needs available

Features

- Boil– Whirlpool Combi Vessel for the mixing of your water with malted base

- Dual Stage Heat Exchanger: For knockout at precision temps for fermentation

- Infusing Vessel: For your fruit, concentrate, spice, or hop additions that are not in the boil

- Integrated CIP Assembly

- Optional Steam Condenser

- SPX class c pump with ABB motor assembly integrated into customizable hard-piped design

- IFM temperature probes and connectivity

- Siemens 4″ HMI to control pump speed, vessel temperatures, and lighting. All electrical components UL certified

- Grated false bottom to support your scoby at manway-level

- 17″ x 13″ manway designed for easy scoby removal

- Co2 / o2 stone located under false bottom for oxygen dosing or carbonation

- Tangential inlet for mixing fruit and flavorings

- Designed to work with the deutsche tilting infuser

- Single-wall or glycol jacketed models available

- Rated to 29 psi

- Full CIP capacity

- Custom options available

- Insulated, jacketed tank for hot or cold steeping applications

- Standard sizes= 150, 225, 300, 450, 600 gallon

- Automated control system with panel

- Complete sanitary hard-piped process and cleaning piping with centrifugal pump

- Variable-frequency motor driven agitator with material out plow

- Dual stainless-steel filter columns for selectable micron bag filters

- Power available in 240v (3ph) or 480v (3ph) for all systems and 220v (1ph) for 300 gallon systems and smaller

- Custom adaptions to meet your process specific needs available

Interested in Craft Brewing Equipment?

Complete the form and our team of experts will contact you to offer you the best solution.

Contact Information

Phone

+1 305 827-9480Related Products

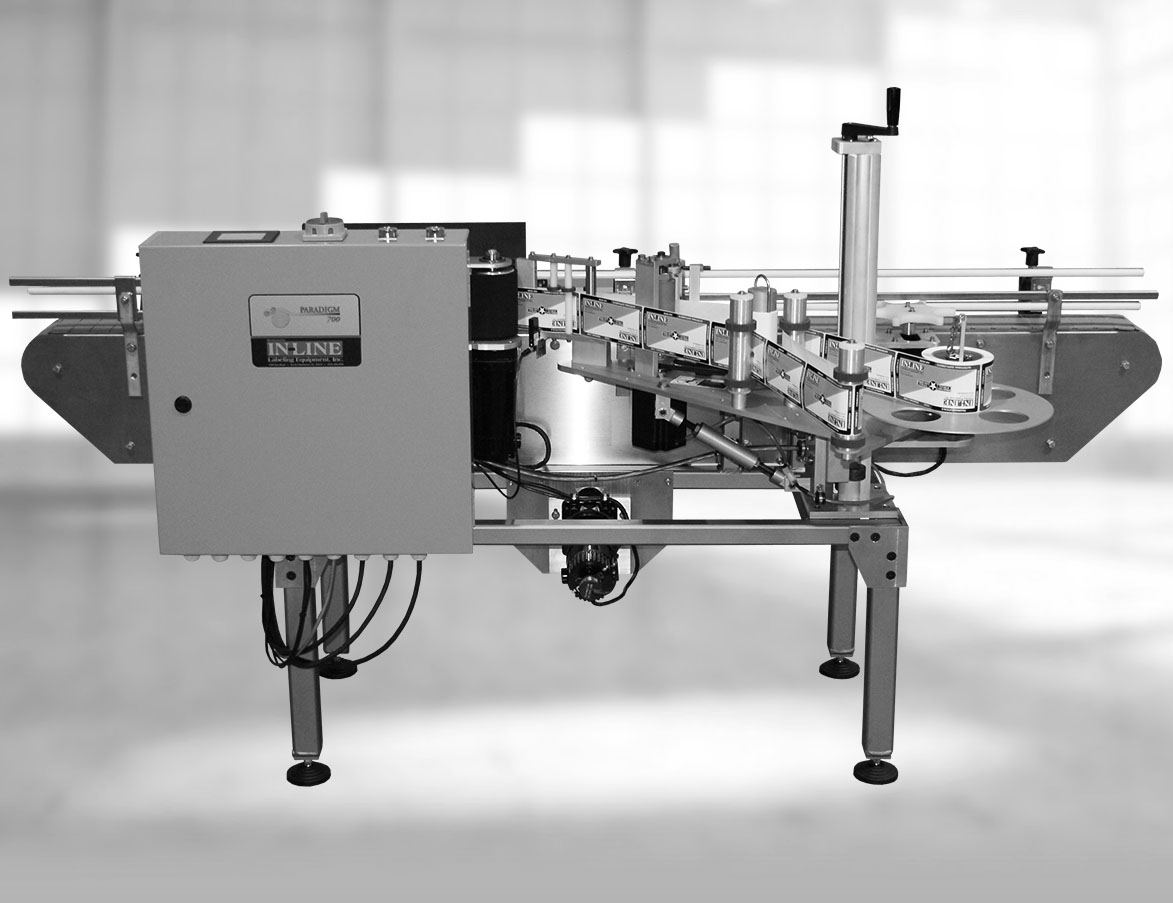

Sistemas Post-Fill Ska Fabricating | Empaque Después del Llenado

Los sistemas post-fill de Ska Fabricating ayudan a mover y organizar los envases...

Fermentadores y Tanques

Los fermentadores Uni-tank (Unitanques) y los Brite Tanks (tanques de cerveza ...

Equipo de cervecería a medida

Los sistemas de Deutsche están diseñados meticulosamente para adaptarse al proce...

Ska Fab Microbus | The Smallest & Most Compact Can Depalletizer

Capable of speeds up to 30 CPM, the Microbus depalletizer is optimized for the s...